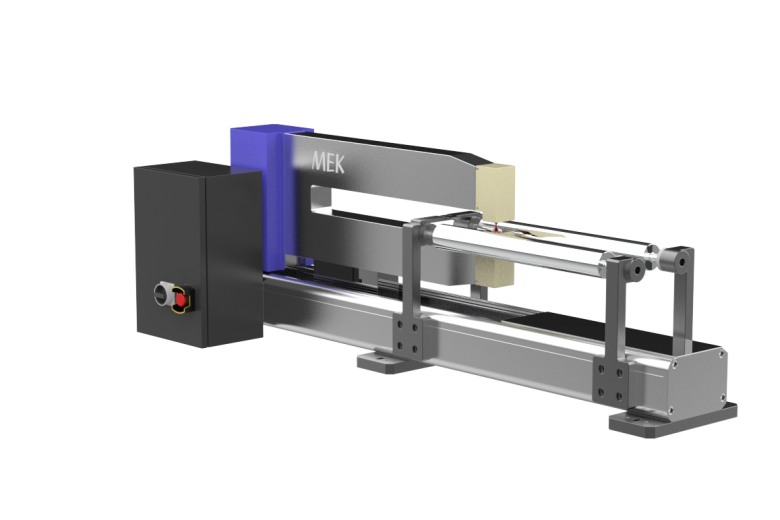

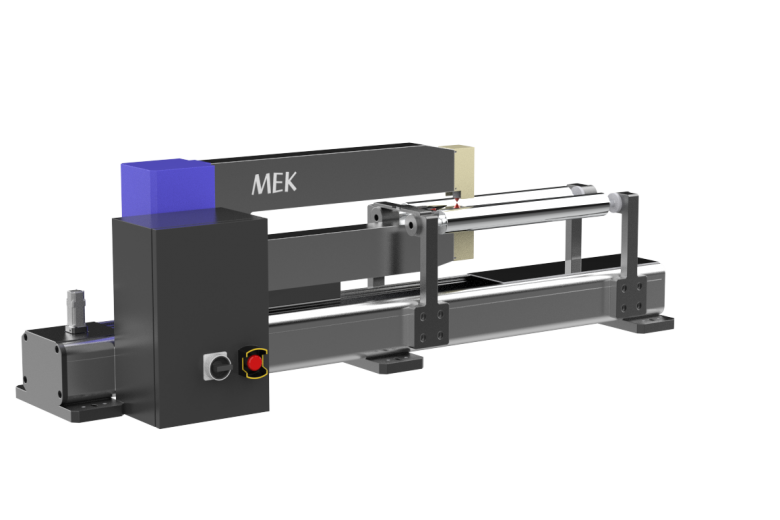

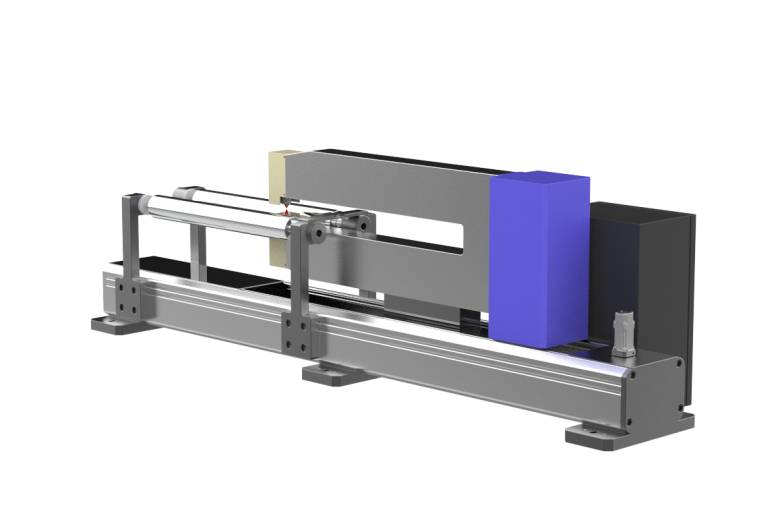

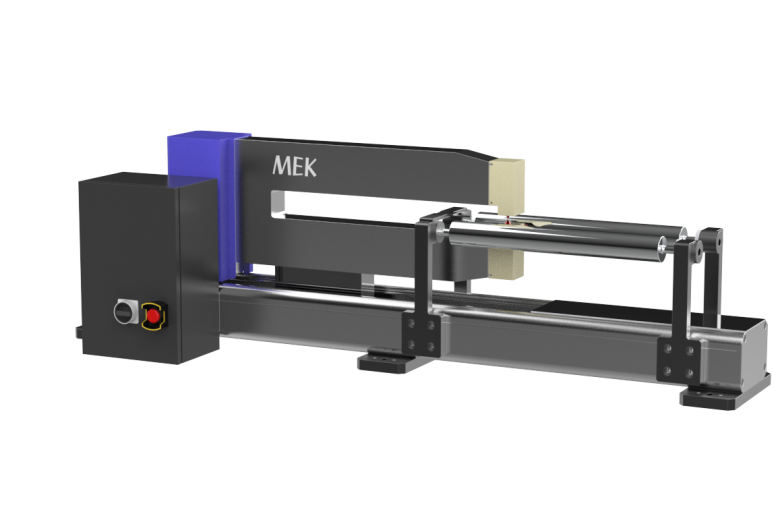

1050 Thickness Gauge

본문

페이지 정보

SPECIFICATIONS

| Description | |

|---|---|

| Application | secondary battery electrode plates,Sheet, plate extrusion |

| Range | 0.03mm~3.6mm/0.3~30mm |

| Width | max. 1,000mm(C-Frame), 2,000mm(O-frame) |

| Pitch | 1mm (0.5-10mm) |

| Spot size | 70µm/300µm |

| Scanning Speed | 150mm/sec (50~350mm/sec) |

| Operating temperature | Up to 45℃(60℃) |

| Repeatability | - Reproducibility during base fabric shutdown±0.02µm(10Scan) - Reproducibility during electrode fabric movement±0.2µm (May vary depending on product quality) - Base fabric reproducibility during movement±0.1µm - Sensor resolution ±0.0025µm/0.25µm |

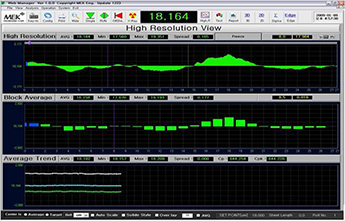

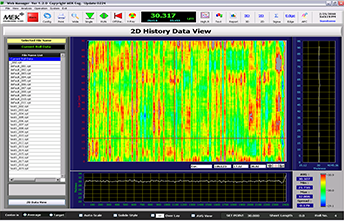

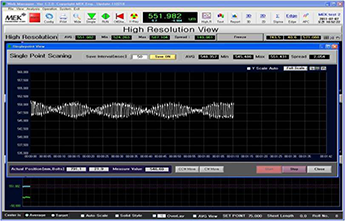

PROGRAM SOFTWARE

MEKプログラムの特徴

• ユーザーフレンドリーな構成 - 直感的なインターフェース

• ユーザーフレンドリーな構成 - 直感的なインターフェース • 利用可能な言語 - 英語、中国語、日本語

• 利用可能な言語 - 英語、中国語、日本語 • ユーザーHMIと計測データ通信(選択仕様)

• ユーザーHMIと計測データ通信(選択仕様) • ユーザーの要求に合わせてカスタマイズ可能

• ユーザーの要求に合わせてカスタマイズ可能

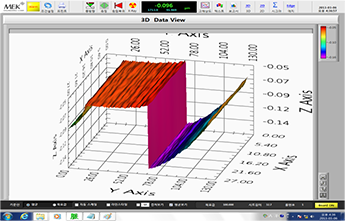

デフォルト画面

| Description | |

|---|---|

| Run Environment | Self-made software based on Labview |

| Data display | gsm (basis weight) / um (thickness) Spatial resolution : 1mm |

| Data compatibility | Microsoft Excel, CSV |

| Functions | Full automatic edge detection Full mapping of entire LOT (2D & 3D reconstruction) Real-time Profile & SPC (Staitstical-Process-Control) Trend chart FFT (Fast-Fourier-Transform) Analysis of MD Profile LOT Statistics & History 4 & 20 Scan Sigma |

| Language | English, Korean, Chinese, Japanese (Hungarian translation available upon request) |

APC(Automatic Profile Control)

MEKプログラムの特徴

- • 最適化された厚さ制御アルゴリズム

- • 迅速な厚さ制御

- • 自動マッピング: センターボルト基準

- • 滑らかなミルロールの外観

- • 数マイクロメートル以内の制御ゲイン自動調整

- • ダイボルト温度フィードバック制御(オプション仕様)

- • MD(マシン方向)制御可能(オプション仕様)

APC適用後のプロファイル変化

Before

APC control begins after the target thickness is changed to 60㎛ to 30㎛

After 5min

Regulates Control Gain of auto-die, reducing variation in thickness

After 10min

Steadily analyzes and controls the thickness profiles

After 15min

Within 15min, produces the best result