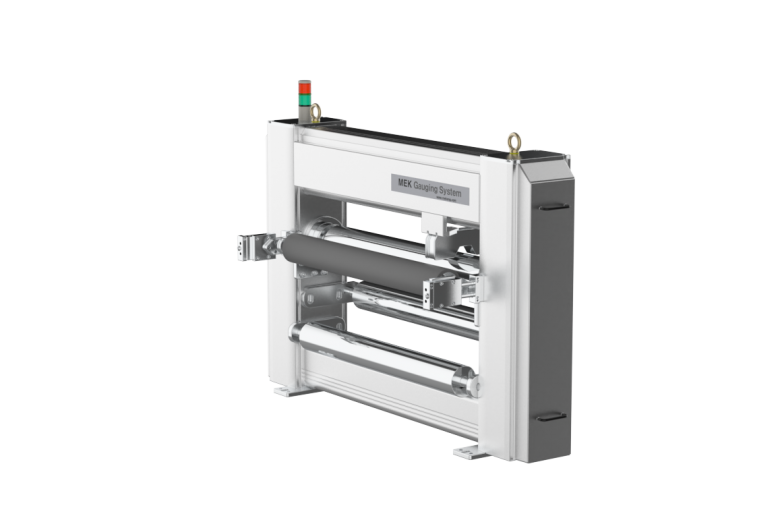

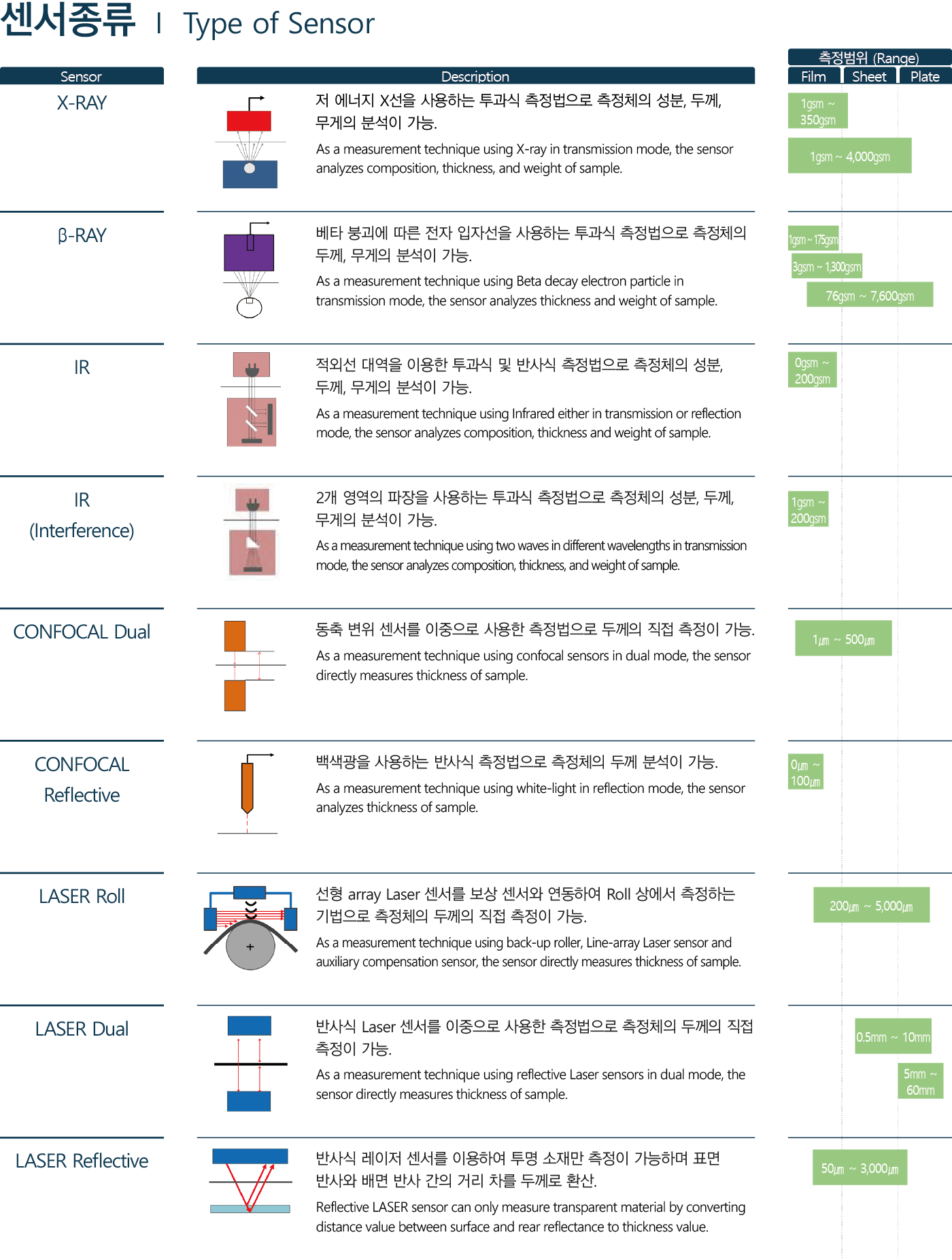

1040 Thickness Gauge

본문

페이지 정보

SPECIFICATIONS

| Description | |

|---|---|

| Application | Film/sheet extrusion with no metallic additive |

| Measuring range | 40-4000µm |

| Measuring width | max 800mm |

| Measurement pitch | 1mm (0.5-10mm) |

| Collimator size | 0.5mm(CD) |

| Scanning speed | 150mm/sec (50~350mm/sec) |

| Operating temperature | Up to 45℃ |

| Repeatability | ±1.5µm or ±0.01% / ±5µm(Sheet) or ±0.1% |

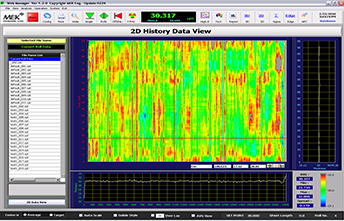

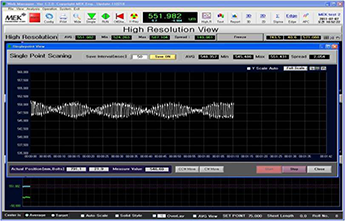

PROGRAM SOFTWARE

Features of the MEK Program

• User-friendly Configuration - Intuitive Interface

• User-friendly Configuration - Intuitive Interface • Language Options - English, Chinese, Japanese

• Language Options - English, Chinese, Japanese • User HMI and Measurement Data Communication (Optional)

• User HMI and Measurement Data Communication (Optional) • Customization to Suit User Requirements

• Customization to Suit User Requirements

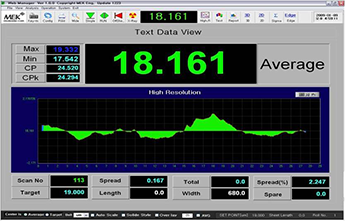

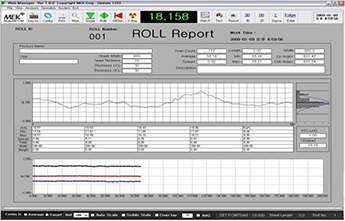

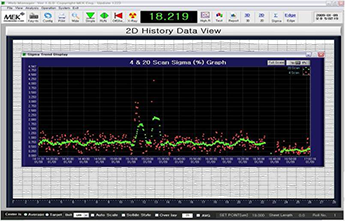

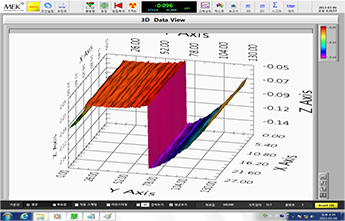

Default Screen

| Description | |

|---|---|

| Run Environment | LabVIEW-based proprietary software |

| Data display | gsm (basis weight) / um (thickness) Spatial resolution: 1mm |

| Data compatibility | Microsoft Excel, CSV |

| Functions | Full automatic edge detection Full mapping of entire LOT (2D & 3D reconstruction) Real-time Profile & SPC (Statistical Process Control) Trend chart FFT (Fast Fourier Transform) Analysis of MD Profile LOT Statistics & History 4 & 20 Scan Sigma |

| Language | English, Korean, Chinese, Japanese (Hungarian translation available upon request) |

APC (Automatic Profile Control)

Features of the MEK Program

- • Optimized thickness control algorithm

- • Fast thickness control

- • Auto Mapping: Center bolt reference

- • Smooth Mill Roll appearance

- • Automatic adjustment of Control Gain within a few microns

- • Die bolt temperature feedback control (optional)

- • MD (Machine Direction) control available (optional)

Profile Changes After Applying APC

Before

APC control begins after the target thickness is changed from 60㎛ to 30㎛

After 5 minutes

Regulates Control Gain of the auto-die, reducing variation in thickness

After 10 minutes

Steadily analyzes and controls the thickness profiles

After 15 minutes

Within 15 minutes, produces the best result