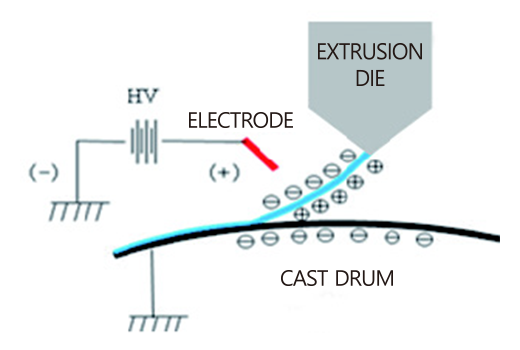

A device that attaches liquid resin from the extrusion die to the cooling roll. Unlike air knives or bead boxes, it operates electrically, providing uniform and superior performance.

Non-contact, electrical method of applying molten polymer on to cooling roll used in plastic film/sheet extrusion process, provides uniform and superior performance compared with air knife or calendar method using nip-roll.

Charging molten polymer using high-voltage electrode creates self-adhering property in the resin by static electric force and it therefore exhibits uniform and strong adhering force on to cooling roll.

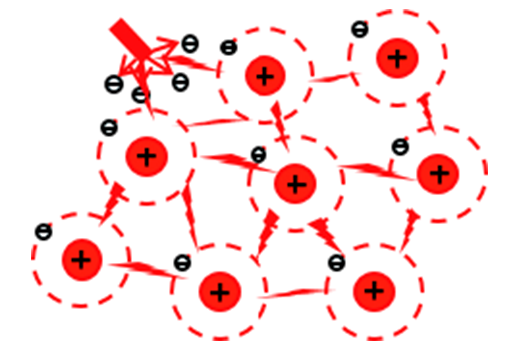

Polarization

Air Molecule lonization By discharge

Film/sheet extrusion process of various resins including PET.

High voltage is applied on the wire or band electrode.

Electrical pinning show uniform and superior performance comparing with air knife and vacuum box. Enables clear and enhanced surface, better CD thickness profile, enlarged product width from less neck-in and less breakage of TDO.

PWire, Doble Wire, 4mm Band, 8mm Ω Type

| Band | ||

|---|---|---|

| Size : 8mm(W) x 40㎛(T) x 300(L) | ||

| Operation Tension :8~25kg Maximum Tension : 75kg |

||

| Precise Grinding On Edge Other Size | ||

| T | L | W |

| 40㎛ | 100 / 300m | 3 / 4 / 8 / 12mm |

| 50㎛ | 90/25m | 3 / 4 / 8mm |

| Wire | ||

|---|---|---|

| Primary Electrode : Ø 0.1 / Ø 0.15 / Ø 0.2 |

||

|

Auxiliary Electrode : Ø 0.3 Tension :0~4kg Type of Pinning System |

Pinning System (Wire / Band)

Operating Panel